Walter, How “dry” do tapes need to be before applying the liquid treatment? Desiccation would seem to require special equipment. Years ago, Sony used to say put them in a warm oven…what do you think of that? What is the best way to dry tapes?

Thanx, LS

There are a couple of ways to dehumidify magnetic media. One is the “warm oven” or “baking” process as some practitioners called it. The concept being to bring the media up to a high enough temperature so as to drive off the moisture that has been absorbed into the polyester matrix that binds the magnetic particles to the plastic film. The absorbed moisture causes the polyester to begin decomposing. If you have ever opened a canister or tape package and smelled a vinegar odor, that is acetic acid break-down product. It was used to create the polyester originally. That is why the goal is to remove the moisture (without harming or damaging the tape). But the the extraction process is one of diffusion. Any moisture closest to the edge of the tape evaporates, or diffuses first. Then moisture that is further down in the tape pack diffuses (restores equilibrium) to replace the “lost” moisture and is subsequently removed from the edge of the tape.

Ovens Can Melt the Tape

Some operators felt that they could speed up this tedious process by running their ovens at higher temperatures! Bad Move! The tape has a significant temperature coefficient. Upon cooling, the tape attempts of reduce its length, and in so doing places enormous hoop stress on the inner layers and hub of the tape. We received at tape from an anguished studio asking if there was ANYTHING that could be done to salvage the tape. The inner third of the reel had literally fused (gel-blocked) into a solid piece of plastic and magnetic emulsion. We could do nothing to help save the information which had been on the tape. The warm oven approach can be helpful with certain caveats in mind. First the temperature increase must be only a moderate one (not higher than 120 degrees F.). The temperature can only be brought up slowly ( 24 hours to reach 120 F.) and return to ambient, even slower – 48 hours. Knowing when an end point is reached is difficult because it is hard to determine when the vast bulk of moisture has been removed.

Better than the Oven

Better than the Oven

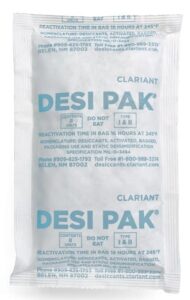

A better way to dry tapes, if you lack a custom vacuum chamber, is to use silica gel desiccant. We have a customer on the East coast that places his media in sealed containers that have a bed of dry silica gel in the bottom of the container. He places the tapes in containers for several weeks and emerge dry and stress free. While time consuming, the process definitely works and is much less of a risk.

Best regards, Walter Davies

The Best Method

Note from Jeff – we are learning that while silica gel does the job, a clay desiccant is better for this application. We advise buying the types in tyvek bags so dust stays contained, then, as Walter says above, put the desiccant and tapes, spaced apart, in an airtight container. Two weeks seems about right for here in California, but if you are in a humid area you might want to go longer. 120g of desiccant is good for a few tapes, adjust time and desiccant up for more humidity.

Note from Jeff – we are learning that while silica gel does the job, a clay desiccant is better for this application. We advise buying the types in tyvek bags so dust stays contained, then, as Walter says above, put the desiccant and tapes, spaced apart, in an airtight container. Two weeks seems about right for here in California, but if you are in a humid area you might want to go longer. 120g of desiccant is good for a few tapes, adjust time and desiccant up for more humidity.

You can find more spirited discussions of methods of drying tapes at tapeheads.net