This question came up in a phone call from a long-time customer. He wanted a recommendation on a drying agent for drying reel-to-reel tapes.

Walter recommended Damp Gone, made by Rutland. You can find it on Amazon or on their website at https://www.rutland.com/p/29/damp-gone—reusable-moisture-absorber

“Drying the tape is a big help in eliminating tape squeal, stiction, and stalling. Tape lovers without access to a vacuum chamber store their tapes (all formats) in plastic boxes with tight fitting lids. The bottom of the boxes have a layer of silica gel. Above that is an open mesh screen. Store the tape above the screen.

Some people seal the boxes with packaging tape to prevent intake of moisture from the atmosphere. Lacking a hard vacuum, the process of moisture removal is determined by the length of time for moisture within the tape pack to diffuse to the surface of the tape, and then move across the surface to the edge of the tape pack. This can take many days, to weeks to accomplish. However, by placing all of your tape into air-tight containers with drying agent, you will already start the process of rejuvenating your tapes – even before you apply the treatment. In the case of cassettes, the diffusion process progresses much more quickly that in R – R and typical video tape formats.

Magnetic media that has been dried and then treated with the preservative is remarkably resilient and can substantially resist the up take of moisture from the air. I do not know of any cassette users that have required re-treatment.” -Walter

A Even Better Method

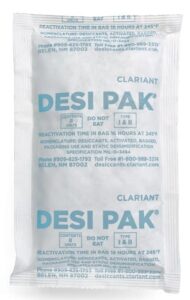

Note from Jeff – we are learning that while silica gel does the job, a clay desiccant is better for this application. We advise buying the types in tyvek bags so dust stays contained, then, as Walter says above, put the desiccant and tapes, spaced apart, in an airtight container. Two weeks seems about right for here in California, but if you are in a humid area you might want to go longer. 120g of desiccant is good for a few tapes, adjust time and desiccant up for more humidity.

Note from Jeff – we are learning that while silica gel does the job, a clay desiccant is better for this application. We advise buying the types in tyvek bags so dust stays contained, then, as Walter says above, put the desiccant and tapes, spaced apart, in an airtight container. Two weeks seems about right for here in California, but if you are in a humid area you might want to go longer. 120g of desiccant is good for a few tapes, adjust time and desiccant up for more humidity.

You can find more spirited discussions of methods of drying tapes at tapeheads.net